Ventilators and Trim

The ventilators and trim are perhaps the most striking features of the barn. The basic function of the ventilators is to provide for air flow through the upper part of the barn. Originally there were eighteen basic ventilators (six each on the front and back and three on each end) plus two combined ventilator/window units, one in each peak.

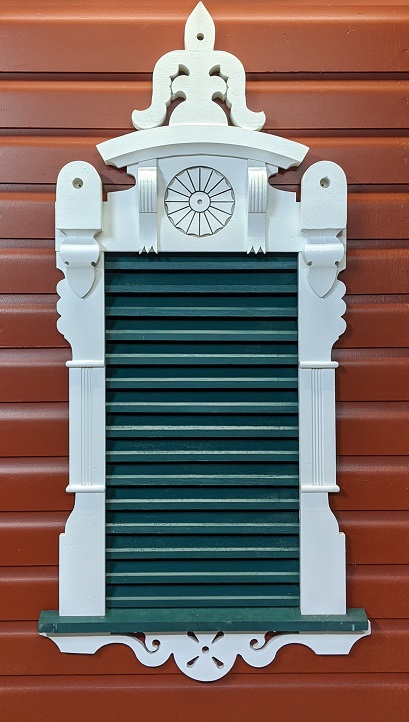

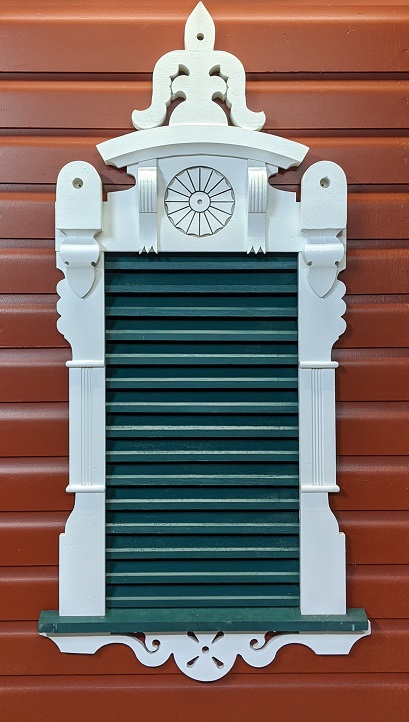

The ventilator shown to the right isn't actually on the barn, but is a shortened version. It was made as a sample that could be portable and also allow a close up observer experience. The red siding measures 3' wide x 5' high, so it can fit in a vehicle for easy transport.

The basic ventilator function was achieved by a stack of slats mounted in a frame. The gaps between the slats allowed for air flow. There were sixty-six slats. The sides of the frame had slots to hold the slats. With one exception, the siding and ventilator components were all restored using cedar for its longevity. The exception to this was the sides of the ventilator frames. Noted earlier, the wooden silo that was removed was made of cypress, also known for its longevity. Cypress is not generally commercially available today as it grows in protected areas. Roughly one hundred years old, the cypress silo staves looked like new lumber after being planed and slotted.

..

When the dairy barn was added in 1950, the center ventilator on the south side of the barn was removed to accommodate the dairy barn roof. The other two on that end were shortened.

The pre-restoration photo above shows the south side of the barn. Other observations in this photo include the old silo and it's need for work on the connector. Also, siding can be seen coming detached from the barn, confirming the need for work to be done. The window at the peak was framed internally to be the same as the one at the other end of the barn. It is unknown why the ventilator part was not present recently. The restoration resulted in the full ventilator/window unit to match that on the north end.

The small window above the dairy barn roof was added when the dairy barn was built. The silo connector had already covered the two windows on the front of the barn. When the dairy barn was added, it covered the remaining window that provided daylight to the first floor corner of the barn. The floor in the corner of the hay mow had a hole cut in it and a structure was added to let the window light go down into the corner pen below and still support hay above.

It is the ornate trim around the ventilator frames and over the doors, however, that make the barn the very special structure that it is. The various pieces that make up the trim were restored based on the original pieces, using either photographs that were traced or drawings based on measurements.

Fabrication of most items was via CNC (computer numerical control) router. This work was done by the owner using a ShopBot Desktop machine. Some pieces required multiple setups. Here is a sequence for one piece, starting with the original piece that had been sawed in half to reveal the cross section. The dimensions of the finished piece are 1-3/4" x 3-1/2" x 11".

..

..

..

..

As many hours went by using the CNC router, the thought that kept coming to mind is that the original builders didn't have a CNC router 133 years ago. Indeed, they didn't have electricity and the question then was how was this work done? Was it done on site or was there a factory somewhere with water-powered, human-powered or other type of energy source at which these pieces were made? Best guesses to these answers will be welcome.

Some changes were made. As an example, the design on the ventilator head board had originally been created by hand, apparently using a chisel. Over the decades of painting, the design had become nearly invisible. In anticipation of future painting, and wanting the design to remain visible in a century, the new design was cut about halfway into the 3/4" thick cedar board.

..