In early 2009, I acquired an Epilog Zing 35 watt laser engraver (www.epiloglaser.com) and have been having fun with it ever since. I bought a second unit in 2013, a Zing 30 watt, which about five years later was donated to the digital design program at Norwayne High School.

Tom Hammond, who manages the 3D Lab at Wayne College (https://blogs.uakron.edu/waynec3) is a good friend and was in the habit of visiting and using our Zing laser engraver. While I always enjoy his visits, it occurred to me that the 3D Lab perhaps should have a laser engraver. So I suggested this and Tom liked the idea, especially when I said that Romich Foundation could cover the cost. We settled on an Epilog Helix. After it was in place, I realized how much nicer it was than the Zing I had. So that was the prompt to upgrade to a Helix here. However, I didn't want to spend $25,000, so I found a used one for half that. Then later I purchased another used one and have found that having two is often a benefit.

The laser engravers are used primarily for manufacturing products, signage and other items and generally for supporting non-profit organizations. As an example, several of the components of the AAC Institute ADA-CAT (Americans with Disabilities Act Compliance Assessment Toolkit) are fabricated using a laser engraver.

The working area of the Helix is 24" x 18". They have two modes of operation, raster and vector. In raster mode they will engrave text and graphics in a manner similar to how an inkjet printer works, by scanning left to right with a specified resolution up to 1200 dots/lines per inch. A rotary attachment facilitates engraving round items, such as mugs, tumblers, goblets, etc. I've engraved natural, finished and painted wood, clear acrylic, anodized aluminum, coated galvanized steel (roofing material), pencils, flooring material, slate, engraving laminate, and more.

In vector mode, generally used for cutting, the laser will follow lines. I've used this feature for cutting wood, acrylic, thin polycarbonate, fish paper, heavy paper, double sticky foam gasket, and other non-metallic materials up to 1/4" thick.

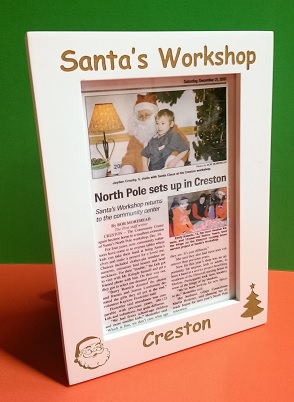

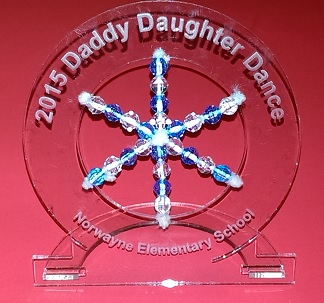

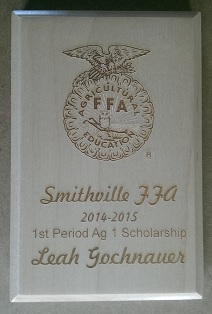

Here are a few examples of things I've engraved and cut.

The above assortment shows a variety of things that can be done with a laser engraver. The base material is laminate flooring, which is available at little or no cost. The green and yellow items are standard laminated plastic engraving material. The surface is removed in the engraving process to expose the core material of contrasting color. With many materials, the laser can cut holes and other shapes and then cut the finished piece out of a sheet.

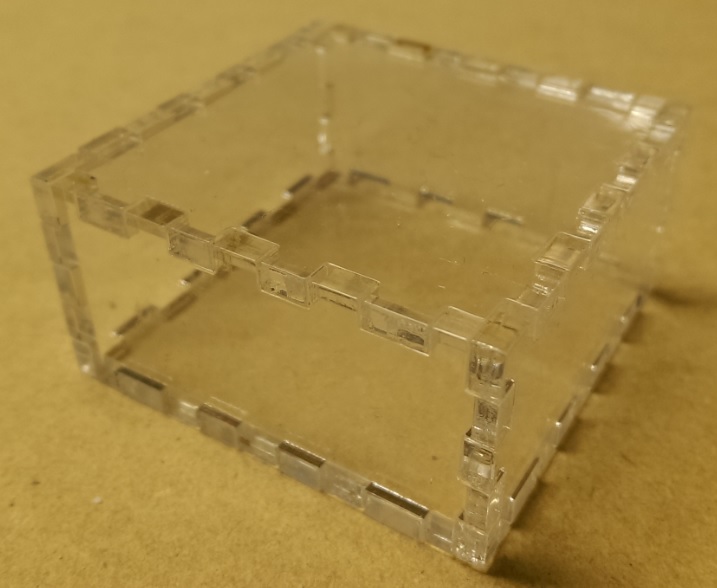

The box below is 2" x 2" x 1" and is made of 1/8" clear acrylic sheet. It is made using a clever free web-based program called MakerCase. (www.MakerCase.com). A tutorial sheet was prepared by the nice people in the Prentke Romich Collaboratory of Think[box] at Case Western Reserve University. The program asks for the desired dimensions of the box, the material thickness, and the type of joint and generates a file that can be downloaded and opened using Corel Draw. The six sides of the box can be moved around to fit on the scrap acrylic you have available and edited, if desired. Just make sure that all the cut lines are "Hairline" thickness.

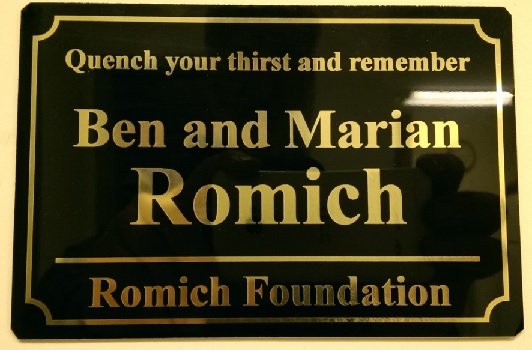

My primary source for standard engraving material is Johnson Plastics. They also have various other materials useful for laser engraving. The brass item below was placed over a donated drinking fountain at the Creston Community Center.

I did the above on baked brown painted aluminum flashing. The laser burns off the paint. The same technique works well with galvanized steel roofing. The color coating, a good contrast with galvanize, is removed to expose the galvanize. The plant markers and garden signs in the Habitat Discovery Garden were done this way using scrap roofing material. The engraved gold charger recognizing Trena Sheppard at the bottom of the garden page was done on this machine as well.

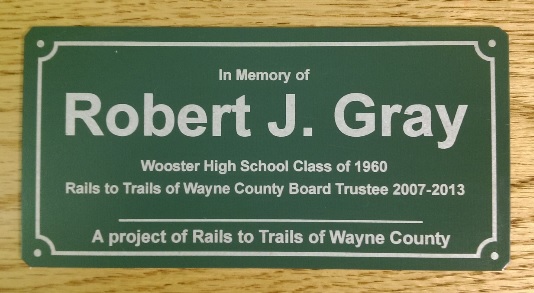

Galvanized steel placards are ideal for outside applications.

My sister Lynn and her husband Art made painted wood blocks and personalized one for each student in both second grade classes at Burbank elementary to commemorate the move to the new Norwayne Elementary School.

My brother Tom is famous among family and friends for running a tight ship when he's in town visiting the farm. I couldn't help myself from creating the above which was posted just outside the entry to the kitchen.

The Habitat Restore is a major source of materials for this. The plaque for Tom was done using maple woodgrain flooring. Settings provided for burning through the surface layer. When insufficient contrast results, stain or acrylic paint can be worked in and wiped off the surface.

This medallion was made using plastic engraving stock with a gold surface appearance.

CerMark is a material that can be applied to glass, metal, ceramic and plastic to facilitate marking with a laser engraver. Dan Kaufman asked for help making an aluminum placard for his friend Rex Miller. Rex had customized a 1954 John Deere 70 tractor and the placard was for mounting on the battery box under the seat. Dan procured a piece of aluminum, sanded the surface and sprayed it with CerMark. He had previously laid out the design and converted it to a .pdf file. The laser engraver did the rest. Dan sprayed the finished item with a clear coat to protect the aluminum from oxidation.

---

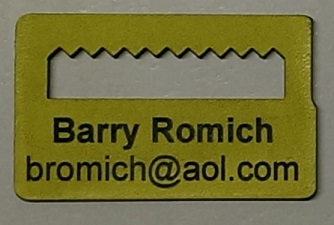

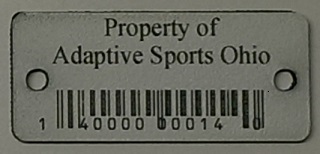

1/16" thick plastic engraving stock was used to make the items below. On the left is a hanger for the engraved chargers, attached with double sticky foam. Center is a keyring. On the right is an inventory tag. Corel Draw, the drawing program used for much of the design work I do, has a barcode function.

---

---  ---

---

---

---

---

---  ---

---